Valve angle defined as the angle between a valve axis and a cylinder axis is one of the most important design factors that may have an influence on valve train design, cylinder head size, in-cylinder flow, etc. In particular, since valve angle cannot be altered during the development process once ba. Here in the image above, the first symbol is of angle valve. In most cases, a globe valve is used as an angle valve. The next symbol is of relief valve that used to protect the piping system or equipment from overpressure. Now the breather valve is used on the cone roof tank. This valve serves the function of the relief valve and vacuum valve.

2007-10-29Valve angle defined as the angle between a valve axis and a cylinder axis is one of the most important design factors that may have an influence on valve train design, cylinder head size, in-cylinder flow, etc. In particular, since valve angle cannot be altered during the development process once basic engine specification is determined at the initial concept design stage, the decision of a valve angle is an important process and the determined valve angle imposes restriction on the potential of the gasoline engine performance.

In this study the effect of the valve angle on in-cylinder flows has been experimentally investigated using a PIV (Particle Image Velocimetry) technique. In-cylinder flows of two test engines that have different valve angles have been measured at four different horizontal and three different vertical planes during intake and compression processes. During the intake process, the result shows that the intake flow of the conventional engine in horizontal plane is more complicated than that of narrow angle engine and the flow in vertical plane is rapidly decayed at the end stage of intake process. The flow pattern of the narrow angle engine is well arranged in horizontal plane and the vertical component of the flow remains so high that forms large scale strong tumble flow. During the compression process, the flow pattern is well arranged compared with intake flows and basic tumble flow structures are maintained until the end of the compression stage regardless of the valve angle.

DOI: https://doi.org/10.4271/2007-01-4045

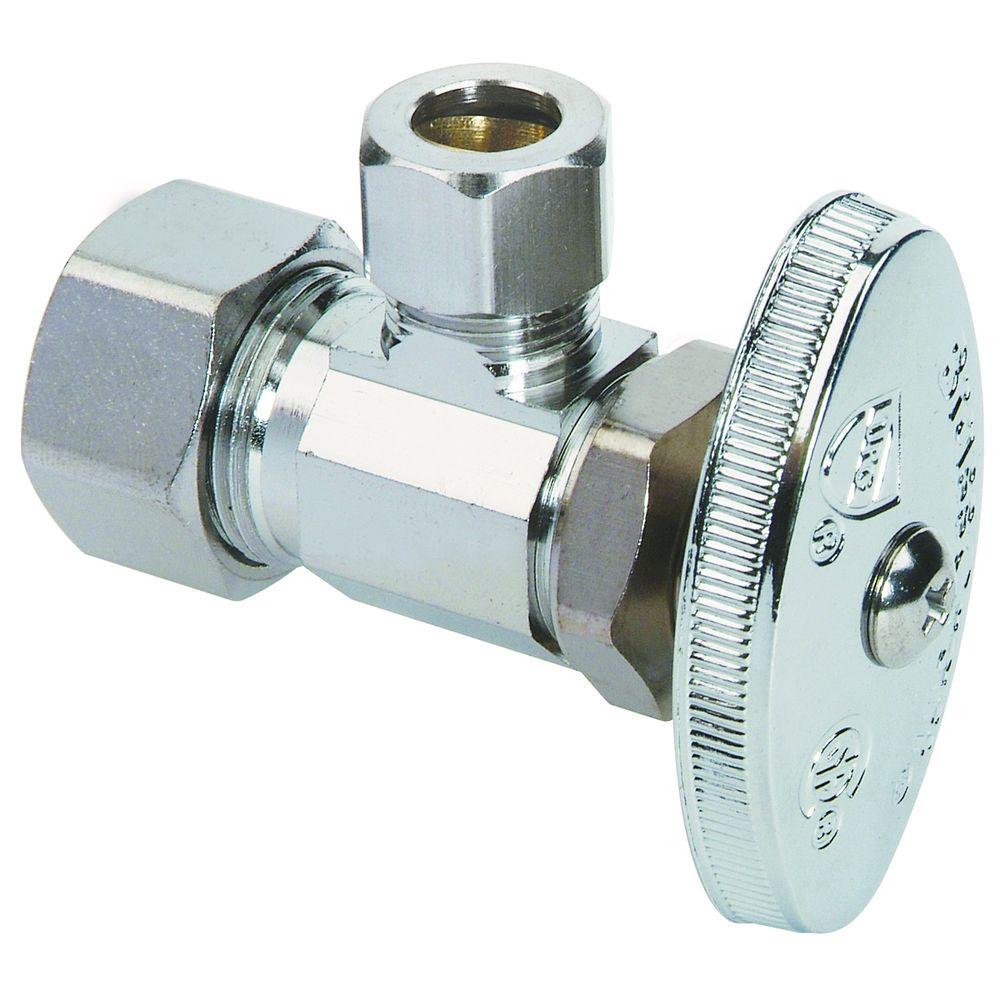

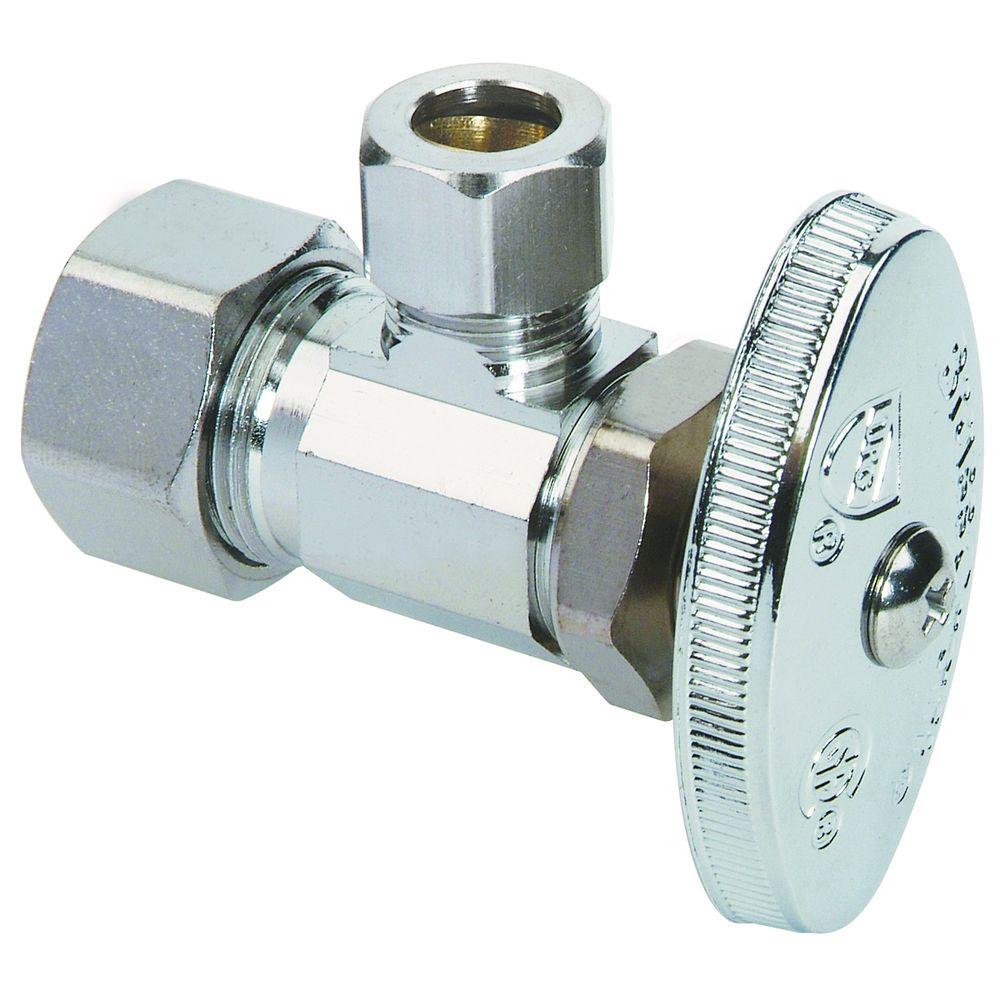

Right Angle Ball Valve

Citation: Kim, M. and Ohm, I., 'The Effect of Intake Valve Angle on In-cylinder Flow during Intake and Compression Process,' SAE Technical Paper 2007-01-4045, 2007, https://doi.org/10.4271/2007-01-4045.

Download Citation

Affiliated: The University of Texas at El Paso, Seoul National University of Technology

Right Angle Globe Valves

Event: Powertrain & Fluid Systems Conference and Exhibition

e-ISSN: 2688-3627

Related Topics:

SAE MOBILUS

Subscribers can view annotate, and download all of SAE's content. Learn More »

We also recommend: TECHNICAL PAPER

Geometric Parameters of Four-Valve Cylinder Heads and Their Relationship to Combustion and Engine Full Load Performance

940205

TECHNICAL PAPER

INA EcoValve A Continuously Variable Valve Lift (CVVL) System

2004-01-1391

TECHNICAL PAPER

Right Angle Gas Valve

Fundamentals of Valve Design and Material Selection

Angle Valve Meaning Definition

660471