- Asme Sec 1 Welding Acceptance Criteria Chart

- Weld Acceptance Criteria Chart

- Welding Acceptance Criteria Examples

- Welding Distortion Acceptance Criteria

- Stud Welding Acceptance Criteria

- Spot Welding Acceptance Criteria

- Weld Acceptance Criteria

Asme Sec 1 Welding Acceptance Criteria Chart

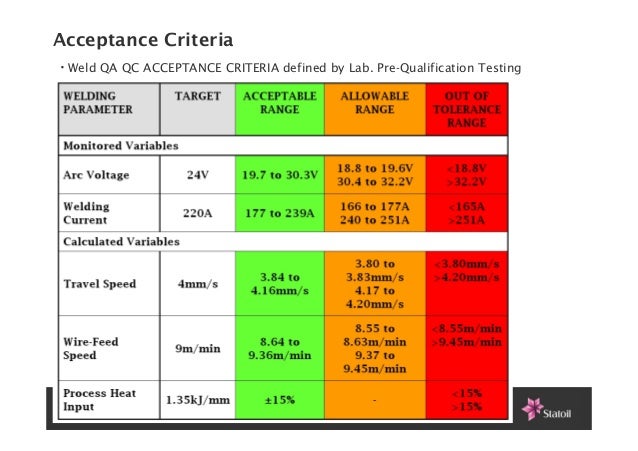

Discoloration in the Heat-Affected Zone: The Discoloration Acceptance Criteria for welds and heat-affected zones (HAZ) as published in ASME-BPE Section MJ applies only to the heat-affected zones of stainless steel components. It is believed that discoloration in 316L is a result of contaminants that degrade the corrosion resistance of the HAZ. In evaluating weld quality, inspectors should make accept/reject decisions based on comparison of the discontinuity with the applicable acceptance criteria as shown below. Necessitate repair of the weld or adjustment of the welding process parameters or both. This occurs when the imperfections exceed the acceptance criteria specified in the standard. BS EN ISO 6520-1 provides the following definitions:. Imperfection: any deviation from the ideal weld. Defect: an unacceptable imperfection. Video about welding inspection education It covers topics below welding defects covered in AWS D1.1 acceptance criteria for the welding defects porosity this.

Preamble: this article has been published in the December 2015 issue of the Canadian Welding Association's Welding Journal.

When welds fail in service, the extent of failure analysis performed is dependent on how it may have affected life, property value or production. These investigations provide feedback that over time has influenced the development of weld quality acceptance criteria for various types of welded structures. This article suggests the why, how and what of inspecting, evaluating and trying to improve weld quality.

To play a role in preventing the failure of welds, the Inspector should have a clear understanding of these aspects of weld quality:

Weld Acceptance Criteria Chart

- What aspects or characteristics of a weld contribute to its fitness for purpose,

- What are the available and appropriate inspection and/or test methods that should be used to assess those quality characteristics,

- What is the relevant acceptance criteria and how is it applied in evaluating the magnitude of various types of weld quality issues,

- Knowing the process variable that contributes to defective welding enables the Inspector to play a role in preventing those defects in future work.

1. What can be inspected and/or tested

Welds can fail in service due to defective characteristics in these categories:

a) Structural Soundness Discontinuities: Imagine looking through a weld and if you see anything other than weld metal, this is a loss of soundness. Things like porosity, cracks and lack of fusion should not be in the weld and are typical discontinuities in this category.

b) Geometric Discontinuities: Welds can fail because they are the wrong size or shape. Undersize welds are typical geometric discontinuities but welds that are oversize can also provide negative consequences due to the additional heat input causing more distortion. Shape also needs to be considered as sharp changes in direction are stress-risers which is why most codes also have limits on the maximum height of reinforcement permitted in groove welds.

c) Property Discontinuities: Welds that are the correct size and shape and pass ultrasonic inspection with flying colours can still fail in service if the mechanical and/or chemical properties do not match the application conditions and loading.

Welding Acceptance Criteria Examples

2. Methods of inspection and testing

Weld quality can be inspected for the first two categories using appropriate NDE methods and/or gauges during visual inspection. Weld quality for property characteristics however is not inspected but instead is verified by first qualifying a particular welding procedure and then monitoring production welding to ensure procedures are followed. This verification will include mechanical and/or chemical testing to assure the weld meets required application properties.

Welding Distortion Acceptance Criteria

The inspection method used is selected based on why welds are being inspected in regards to the consequence of failure. In some cases a simple visual inspection will suffice while in situations, it is accompanied by one or more NDE methods to examine the weld inside and out. Often, the method of weld inspection is specified by the relevant code or standard and in the absence of those requirements, may be specified by customers or the responsible Engineer.

In some quality assured environments, the inspection method is detailed in a documented procedure to assure reliable and consistent results. These documents list the steps of inspection in sequence and list requirements for variables, calibration, etc. Even something as simple as visual inspection is sometimes defined in documented procedures to ensure proper inspection tools are used, suitable illumination, competent Inspectors and reporting requirements are met. Shown below are some various visual inspection tools that may be required for weld inspection.

3. Weld quality acceptance criteria

Inspectors examine welds looking for 'discontinuities' which are changes in the intended structure or properties of a weld. Considering the structural soundness category of quality, anything other than clean metal within or beside the weld is considered a discontinuity. If found, Inspectors should not immediately reject the weld quality but instead evaluate the discontinuity found in comparison to the maximum permitted in the relevant acceptance criteria. Discontinuities that exceed the acceptance criteria are then identified as 'defects' and must be repaired or the item scrapped while discontinuities within allowable limits may be recorded as 'flaws' in an inspection report and do not require repair.

Ideally, welding acceptance criteria is defined in a tangible format with clear direction on what gets accepted vs rejected with different formats and combinations used based on the type of discontinuity. In some cases, statements are used such as 'no cracks' provide an easy route to the accept/reject decision. The rationale behind zero tolerance for some discontinuities like cracks is they are prone to propagation or growth with successive loading over time ultimately leading to complete failure.

In other cases, individual discontinuities must be measured with some type of dimensional tolerance then applied. Let's look at the ways to define porosity acceptance criteria listed below from a structural steel welding standard:

A magnifying glass and a visual guide showing these magnitudes of porosity would be useful in properly assessing the acceptance status of porosity. Even more challenging than porosity perhaps is the criteria to assess undercut shown below from this same structural welding standard. This complexity in assessing discontinuities such as porosity and undercut can sometimes lead to short-cuts in rejecting discontinuities that are in fact acceptable per code acceptance criteria. Undercut should be measured with a suitable gauge like the pit depth gauge illustrated earlier.

Stud Welding Acceptance Criteria

One last option that is sometime used for weld acceptance criteria is sketches or actual samples showing the maximum magnitude of a specific discontinuity permitted before rejection.

These examples illustrate some of the important information the Welding Inspector needs prior to beginning to assess weld quality which may need to be defined by the responsible Engineer:

- What is the relevant code and/or acceptance criteria?

- What is the nature of the loading on the welded structure?

- Are primary stresses along or across the weld?

A note of caution in applying acceptance criteria is that in some cases, the criteria to apply is conditional on the method of inspection or NDE. Another consideration is that inspection of some quenched and tempered HSLA steels must not be done till 48 hours after welding as these are more susceptible to hydrogen initiated cold cracking.

4. Preventing recurrence of failed welds

While identification and evaluation of welding discontinuities may be the primary function of a Welding Inspector, they can also play a role in preventing recurrence through root cause analysis and corrective action.

Spot Welding Acceptance Criteria

The ability of any welding process to make quality welds is dependent on the welding procedure used which has variables in the categories listed below. There may be some differences based on which welding process is being used and if it is performed manually or automatically.

Welding is a surprisingly complex process involving a wide range of variables that influence weld quality. When welds are defective, one of more variables not adjusted or controlled properly for the application has been the cause. The Inspector needs to analyze the discontinuity, investigate how it was welded and then problem solve to determine which variable(s) were likely to have caused the problem. When welds have been identified as defective and will be repaired, the Inspector should monitor the repair process carefully.

Weld Acceptance Criteria

Comprehensive weld inspection is a much more detailed process than simply marking weld inconsistencies with a marker for repair. It requires knowledge including welding processes, metallurgy and inspection methods. To ensure this is done correctly, many codes including CSA, AWS and IIW require that Welding Inspectors demonstrate their competence through qualification certification.